Two Queens' Engineers receive

President's Special Award for Pandemic Service

from the Royal Academy of Engineering.

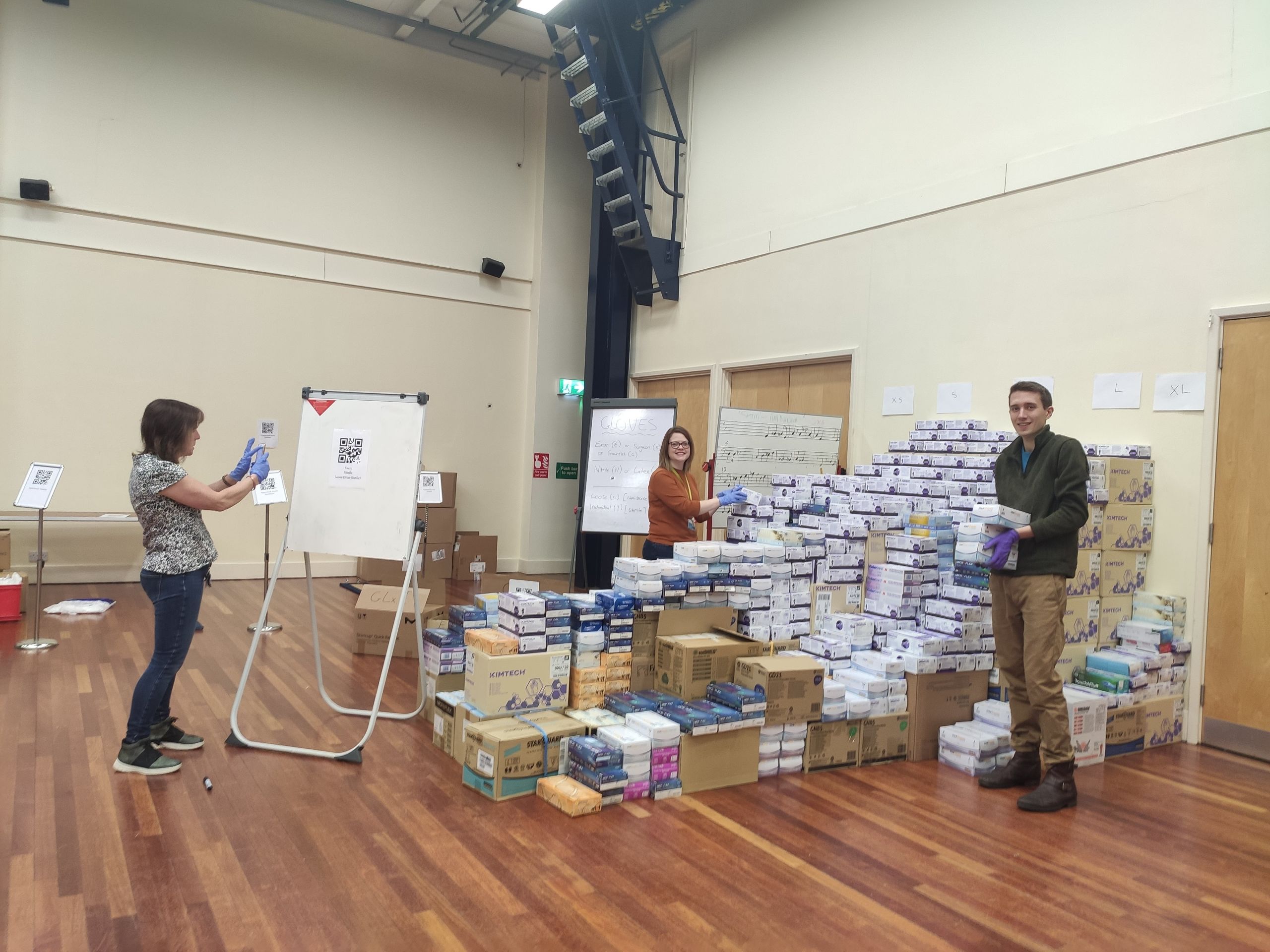

Many congratulations to Dr Christopher Clark (2007 & Bye-Fellow), second from left in the photo, and Rob Glew, current PhD student, who have both received the President's Special Award for Pandemic Service from the Royal Academy of Engineering.

The Royal Academy of Engineering has recognised 19 individuals and teams of engineers for exceptional engineering achievements in tackling Covid-19 throughout the UK.

The Open Ventilator System Initiative

Dr Clark was part of the team behind the Open Ventilator System Initiative, lead by Dr Tashiv Ramsander at Cambridge Aerothermal Ltd. They recieved this award for their development of a high-performance ventilator for manufacture in low and middle-income countries that became the first intensive care quality ventilator to be manufactured in Africa.

In March 2020, as Covid-19 infection rates were rising dramatically in Europe, the number of infections in many low- and medium-income countries remained low. However, it was predicted that towards the summer these rates would start to increase. This was especially worrying due to the low number of ventilators available in the developing world.

In response to these fears, the team at the University of Cambridge and a number of companies within the Cambridge cluster designed a high-performance intensive care ventilator for manufacture in low and middle-income countries. The aim was to develop a ventilator with a price point that was a factor of 10 lower than what was currently available, which could be manufactured from readily available components and which could be manufactured in-country. The result was the first clinical grade ventilator to be manufactured in Africa.

“The result is a design that will save countless lives in the developing world where ventilators are scarce and many that exist cannot achieve the quality of performance that the Open Ventilator offers. It is a scalable solution. The high-performance open-source design will enable companies across the world to make systems wherever they are needed, and at a price that is compatible with the local healthcare systems.”

The Institute for Manufacturing

The IfM team, including Queens' PhD student Rob Glew pictured right, helped local hospitals to make the best use of their resources, streamlining logistics for sourcing and storing vital PPE, informing decision-making on emergency demand, and developing a ventilator sharing system to be used in emergencies.

As hospitals scrambled to make the necessary operational changes needed to accommodate COVID-19 patients, a team of staff and students from the Institute for Manufacturing (IfM) at the University of Cambridge was there to help. Working with clinicians and senior healthcare managers to assess the immediate and emerging operational challenges facing local hospitals, they identified where these could be addressed through the application of engineering capabilities and coordinated the roll-out of solutions.

The IfM team addressed three groups of tasks between March and May in the areas of hospital logistics, personal protective equipment (PPE) delivery and intensive care unit (ICU) equipment development.

“The team gave key support efficiently and skilfully when it was most needed, with no fuss and maximum impact: engineering at its best.The team found a way to work with the clinicians without taking up too much clinical time. They found the problems that needed solving and got on with solving them. They stepped up when they were needed and made a real difference. For this, we should be proud of them.”

More information can be found on the Royal Academy of Engineering website and through the University of Cambridge.